When I read ISO 9001 standard for the first time, I didn’t immediately understand what it was saying. It seemed to be written in a very difficult way. However, if you read the standard after understanding the structure of the standard, it becomes very easy to understand. So, today, I will show you the whole structure of ISO 9001 standard in just five minutes.

Text follows the Movie

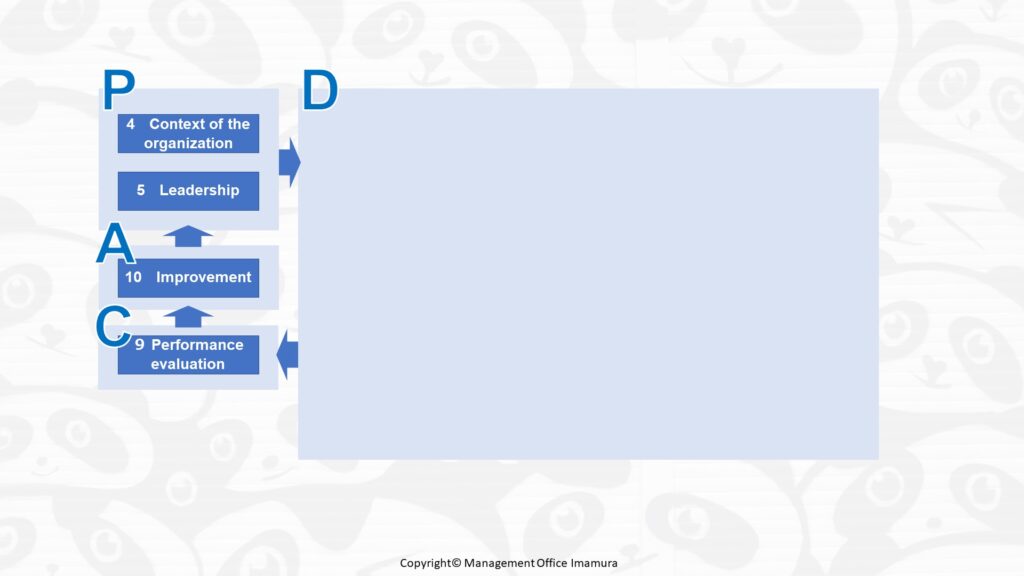

PDCA cycle for which top management is responsible

Here are some blue squares. These are what-we-call PDCA cycle, for which top management is responsible.

To lead the organization effectively, top management must stay informed about internal and external issues as well as customer demands, as required by ISO9001 clause 4. Based on them, top management must exercise leadership according to clause 5. These clauses serve as planning for the organization to work together towards achieving management goals.

So far, we have covered the Plan phase of top management. The next step, Do phase, involves executing the plan, and it can be considered as the core component of ISO9001 management system. After putting the system in place, Top management evaluates whether management goals have been truly achieved, according to clause 9. If something was lacking or failed, it is necessary to make improvements to do better. This corresponds to clause 10, "Improvement." Top management is responsible for carrying out this cycle, for example, annually.

PDCA cycle for which managers are responsible

Now let's examine the PDCA cycle, for which managers are responsible, represented by orange squares. These orange squares can be considered as the main body of ISO9001 management system, and mainly outline the tasks that managers are required to carry out.

In ISO9001 clause 6 "Planning," the potential risks surrounding the company must be identified and quality objectives must be also established. Clause 7 requires that you be prepare the people, tools, equipment, and work environment necessary to achieve these objectives. These clauses constitute the Plan phase of management system.

The next part, Do Phase, involves executing the plan. In ISO9001, this corresponds to clause 8, "Operation.” This clause 8 outlines the actions to be taken at the operational level. More concretely, it provides specific methods for manufacturing and service provision in the front-line. Later, I will explain in detail. Following this, you evaluate whether ISO9001 management system has been effective. If it falls short or fails, you make improvements to enhance performance, similar to the top management cycle, the blue squares. As a manager, you should carry out this cycle on a quarterly or monthly basis, for example.

PDCA cycle for which front-line workerss are responsible

And finally, let's look at the PDCA cycle for which your front-line workers are mainly responsible. These are indicated by pink squares. These pink squares represent the key tasks that your front-line workers in the field should undertake. It is a series of cycles pertaining to day-to-day operations. Specifically, ISO9001 clause 8, "Operations," applies, covering the planning, production, and delivery of services for each work project.

First, clause 8.1 to 8.4 are used to create a plan for each project. This phase encompasses efforts related to meeting customer requirements, design and development, as well as approaches to deal with your subcontractors and partners.

Clause 8.5 pertains to the actual manufacturing and service delivery, while clause 8.6 concerns inspection prior to offering it to the customer. This constitutes the Do Phase. Afterwards, you assess whether the manufacturing and service provision for each project were successful. If something didn’t go well, you make improvements. This is the same as the cycles of top management and managers. However, in the front-line cycle, clause 8.7, "Control of non-conforming outputs," is introduced in the Action phase. Regardless of the type of manufacturing or service provision, the potential for producing defective products or providing incorrect services cannot be entirely eliminated. In such cases of defects or non-conformities, clause 8.7 pertains to the measures required to prevent them from being transferred to the customer.

I hope that the concept of “nested PDCA cycles” for each of these three levels is now clearer and easier to understand. This framework provides a comprehensive overview of ISO9001 standard.